Your Cart is Empty

Please call or email howesales@howeracing.com if you have issues placing international orders.

Please call or email howesales@howeracing.com if you have issues placing international orders.

Along with fire and brake failure, a stuck throttle is one of the most feared safety risks in racing. Considering even the most robust car and safety equipment have limitations, it is fortunate this is a rare event. The conditions that can cause a throttle to stick are not always foreseeable. However, you can drastically improve your odds by learning from others, so we are sharing some of our experiences.

Most throttles connect to the pedal by a solid linkage or a cable. Solid linkages provide a means to pull back on the pedal. Still, they can be difficult to route around engine components such as exhaust headers and airboxes. With a carburetor, the most common problem is maintaining clearance between the front of the linkage and the air filter housing. Most race cars have tall manifolds and carb spacers, which makes fitting an air filter element under the hood only possible with a dropped filter housing. Dropped housings confine the typical Holley carburetor lever into a tight space. Creating linkage clearance can require the base's indention near the throttle, which is risky because the one fastener in the center permits the housing to rotate. If the housing base turns while the throttle is open, it can jam against the linkage. This problem can also happen with the offset-type filter housing.

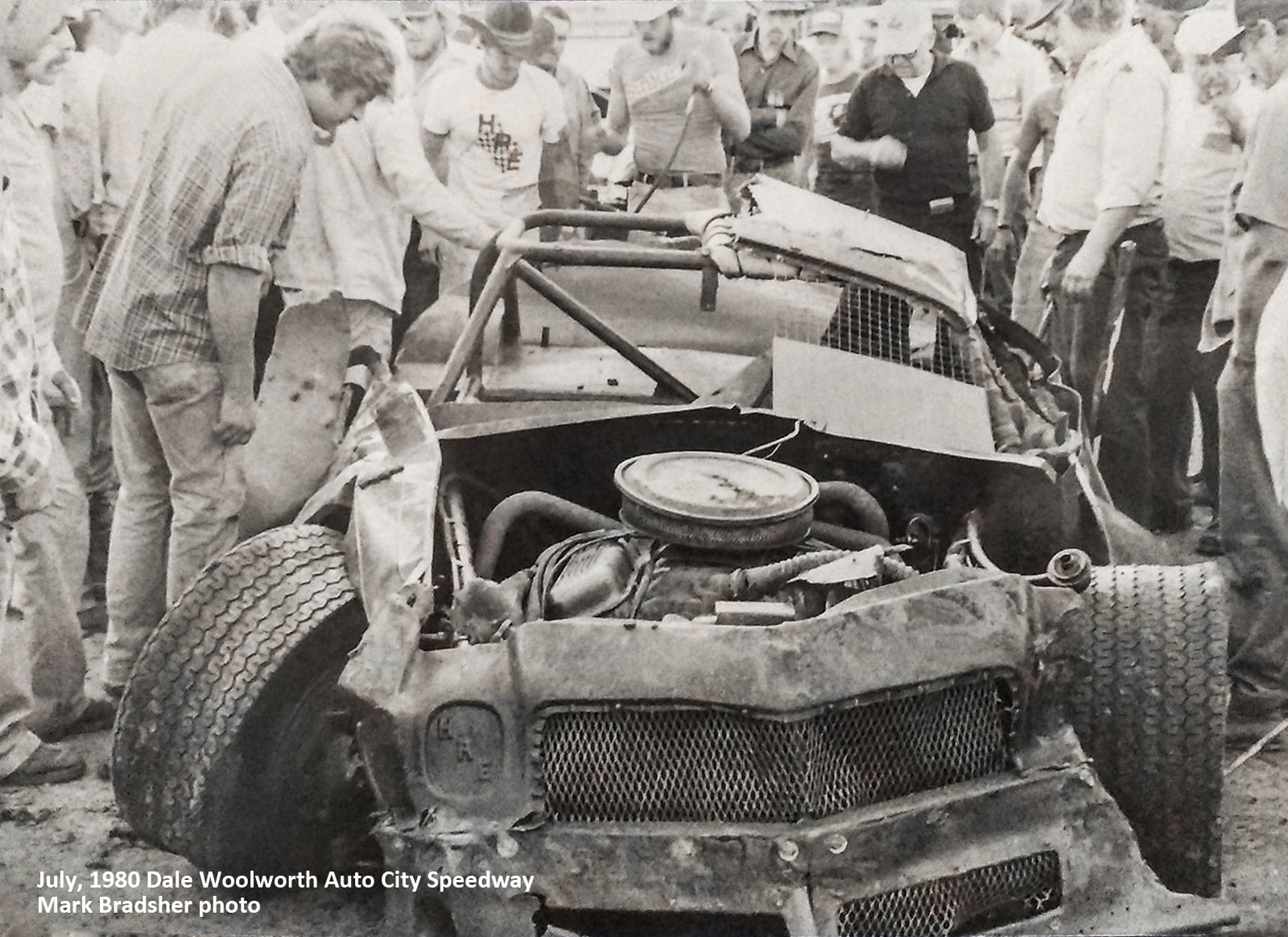

Such was the case in 1980 when Dale Woolworth smashed through the turn-three guard rail at Auto City Speedway, nose-first into the pit area, narrowly missing a crew member. Dale had his bell rung and some bruises, but things could have been far worse. The best way to prevent this problem is to lower the carburetor and reduce the drop in the housing. Still, not many racers will sacrifice the associated loss in performance unless the rules require doing so. The next best measure is to attach the filter housing to the cold air box to prevent it from turning, and if you don't use a cold air box, then secure the base from rotating by another means.

With EFI, the throttle body lever and pedal are often on opposite sides of the engine. All racing linkages are, in some parts, improvised and articulated in multiple places to transfer the motion. The installer must time the position of all levers not to create a toggle-lock. A toggle-lock happens when arcs in a mechanism travel over their center. Linkages have a series of spherical rod end bearings held inline with jam nuts that, if loosened, can bind. The more bearings used, the more potential for problems. Because linkages are not encased like a cable, they are vulnerable to interference with anything under the hood, such as stones, tire rubber, and even the hood itself. We had an experience with an ASA car in 2004 where the team fabricated a linkage over the intake manifold, and air pressure collapsed the hood onto the linkage and stuck the throttle. Fortunately, the driver switched off the ignition in time for the car to slow, and the hood popped back up. The solution was installing a hood support, but better yet would have been not to place the linkage in this vulnerable location.

Throttle cables have risks of their own. The most notable disadvantage of a cable is it is single-directional, so pulling back the pedal does no good. Cables can wear or break, or you can pull the ends off, which only returns the engine to idle, but a correctly installed cable is less exposed than a solid linkage. Nevertheless, cables can still stick from snags, corrosion, or neglect. In 2013, a driver demolished a TA2 car in turn-six at Road-Atlanta after a homemade cable clamp hooked the end of the fuel rail. Fortunately, the track had a tire barrier and a movable wall to lessen the impact.

It is best to use a heavy gauge throttle cable with the housing sleeve as long as possible to limit cable exposure. Considering what's at stake, we suggest replacing the throttle cable as often as you freshen or replace the engine.

Installing a solid stop for the pedal is a good idea with a linkage or cable. A stop prevents the driver from bending the linkage or breaking the cable, but the stop can also be problematic.

In 2014, a tall TA2 driver bent the pedal to fit his size 13 shoe at Homestead Speedway. Unfortunately, the modification for his big stomper misaligned the pedal with the stop and the edges hooked, locking the throttle open. Fortunately, turn one of the Homestead infield course has a long run-off to NASCAR turn one giving the driver time to switch off the ignition before contacting the SAFER barrier.

We don't have all the answers, but we may have some that others do not. We are glad to hear about your experiences and encourage an open dialogue on safety issues that may prevent someone from repeating a costly mistake.